This is mostly for my own reference, but maybe you can use it too. I build sets every summer for Gotta Sing Gotta Dance and they like to use foamcore set pieces (ie “flats”) because they are so lightweight and easy to manoeuvre.

The problem with 3/16″ foam core is that it doesn’t quite stand up straight on its own and it needs a frame (when standing higher than 4 feet, anyway). So most of my time is spent building lightweight frames for the foamcore to be zap-strapped to.

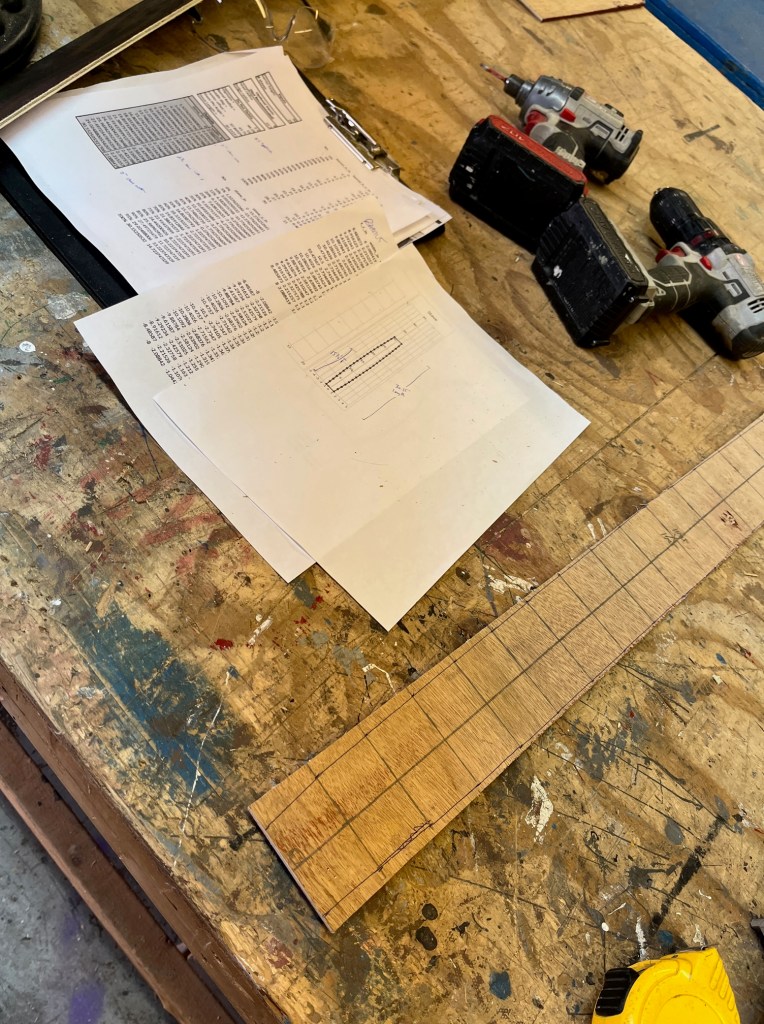

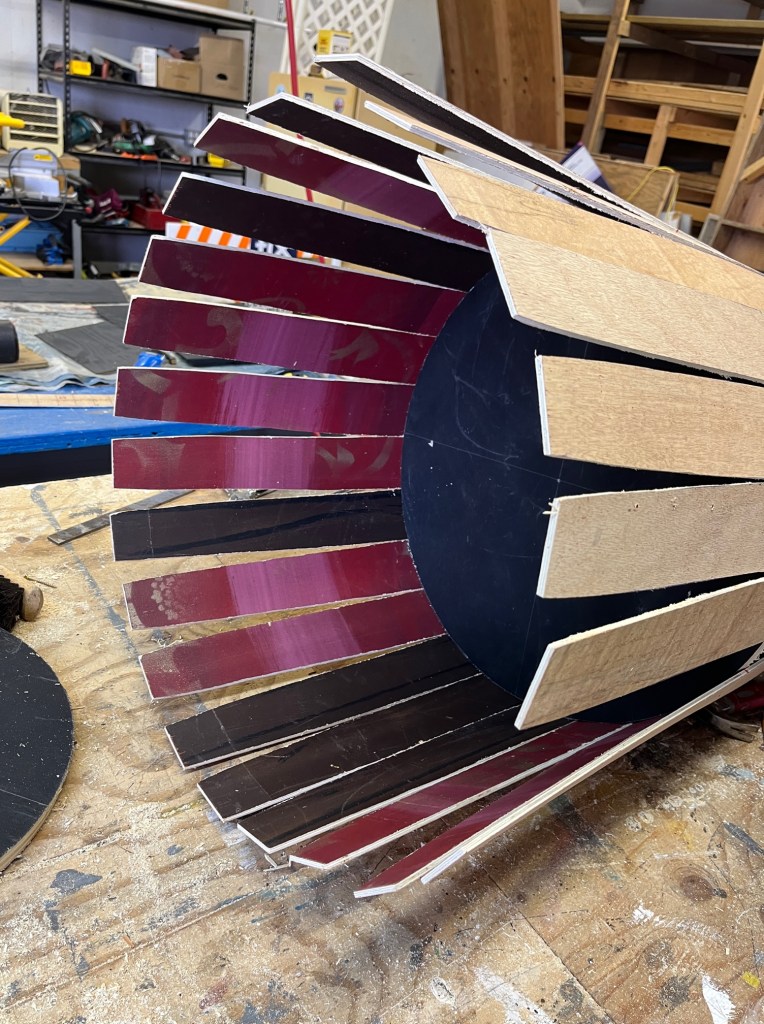

However when the foam core piece is 4 feet high or less, it can be held up with very little effort. I made some wooden blocks that worked quite well for quite a few pieces. Here they are:

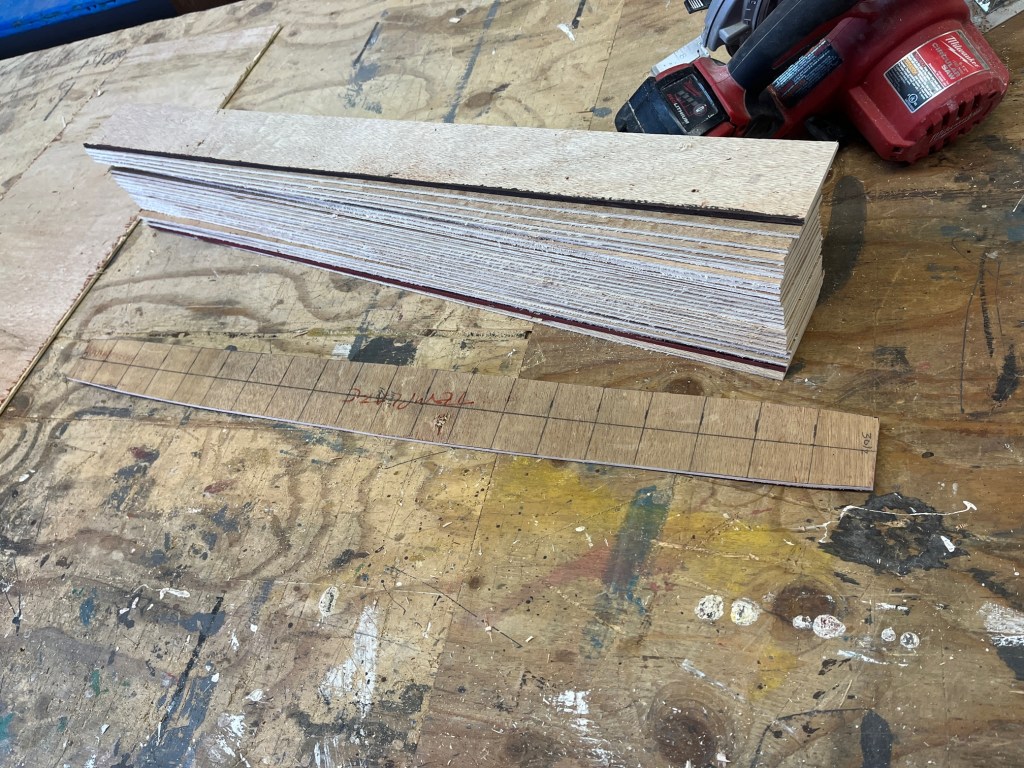

I cut a scrap piece of 3/4 plywood into the odd shape above. The slot is for the foam core to fit snugly in. The angle of the slot is not 90 degrees – it is slanted back slightly (1 or 2 degrees) so that the foam core rests mostly on the back (taller) side.

I then glued+stapled a vertical stick to help with rigidity. Then zap strapped the stick to the foamcore (yes, you can sometimes see it protrude through the front if you look for it)

The zap straps just slide off the sticks if you want to remove the bases for transport. You have a set piece light enough to pick up with one hand, that stands up by itself.

Bonus tip: when painting foamcore, always paint both sides, or you get major warpage.

Bonus tip #2: foamcore is generally more expensive than plywood of the same thickness. But it can be ordered in bulk in 4×8 sheets from your local printshop for some savings.