Gallery 7 Theatre recently presented a play called Glory by Tracey Power. On the surface it is a hockey play about a very succesful women’s team that played in Ontario in the 1930’s. It has a variety of themes, however; and is a different type of play than many I’ve seen. I was tasked with building the (simple) set and as our set designer was out of commission at the time, I also took on the painting and a few of the projections.

Director is Gabe Kirkley, and set designer is Jeff Kiers.

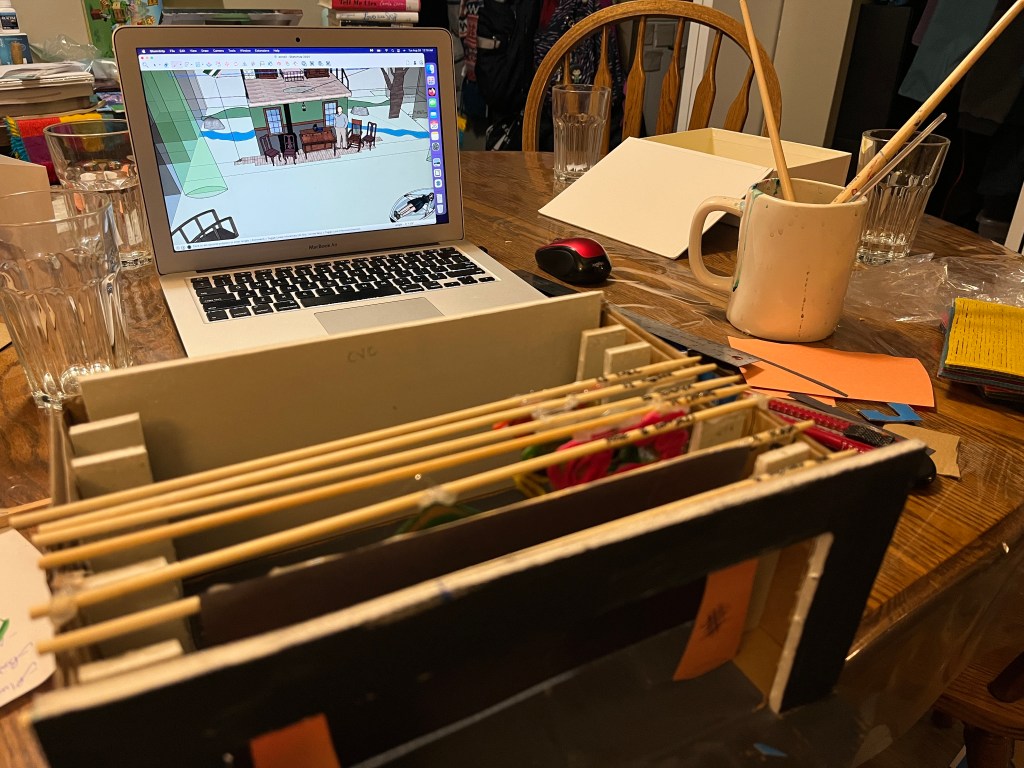

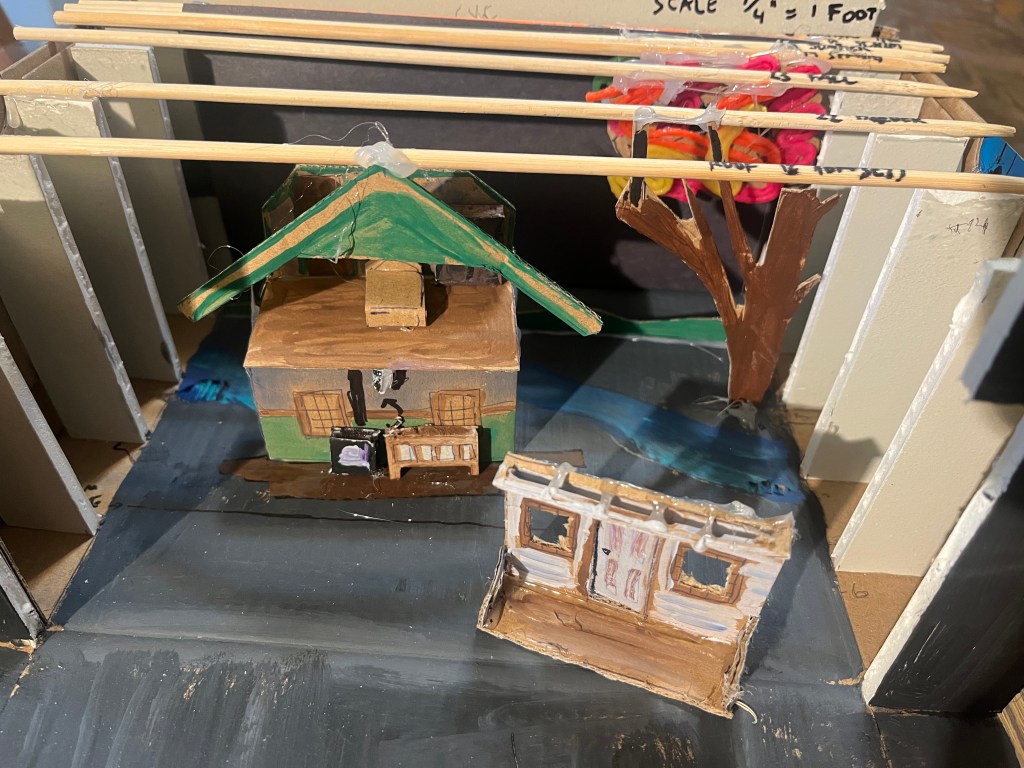

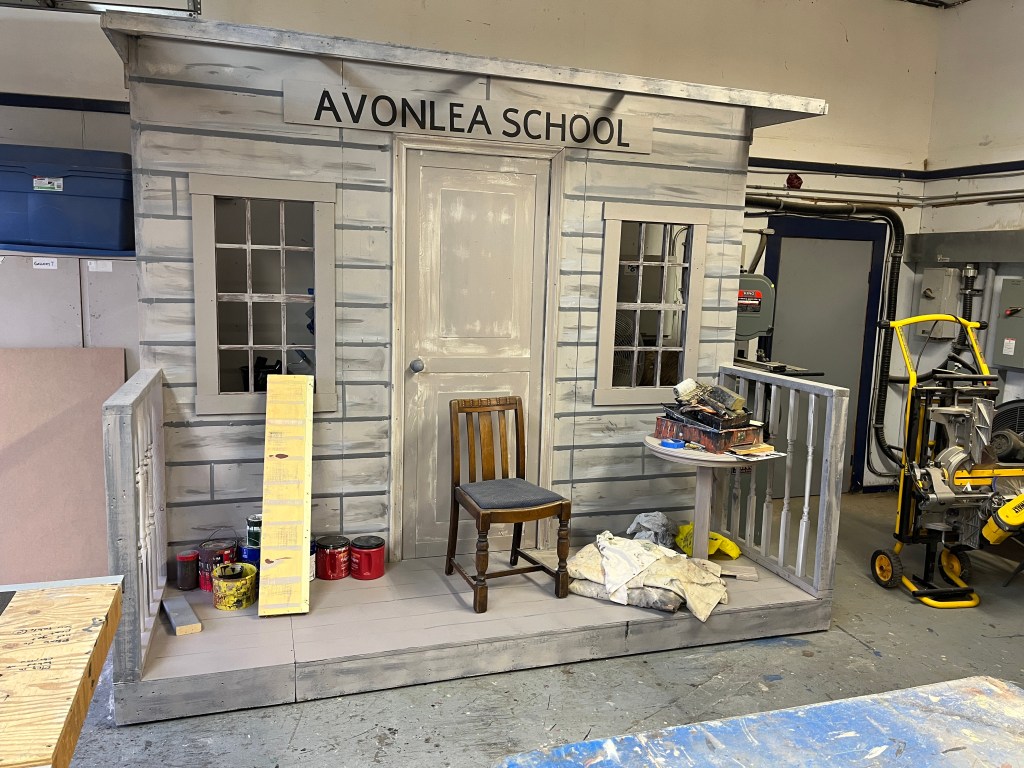

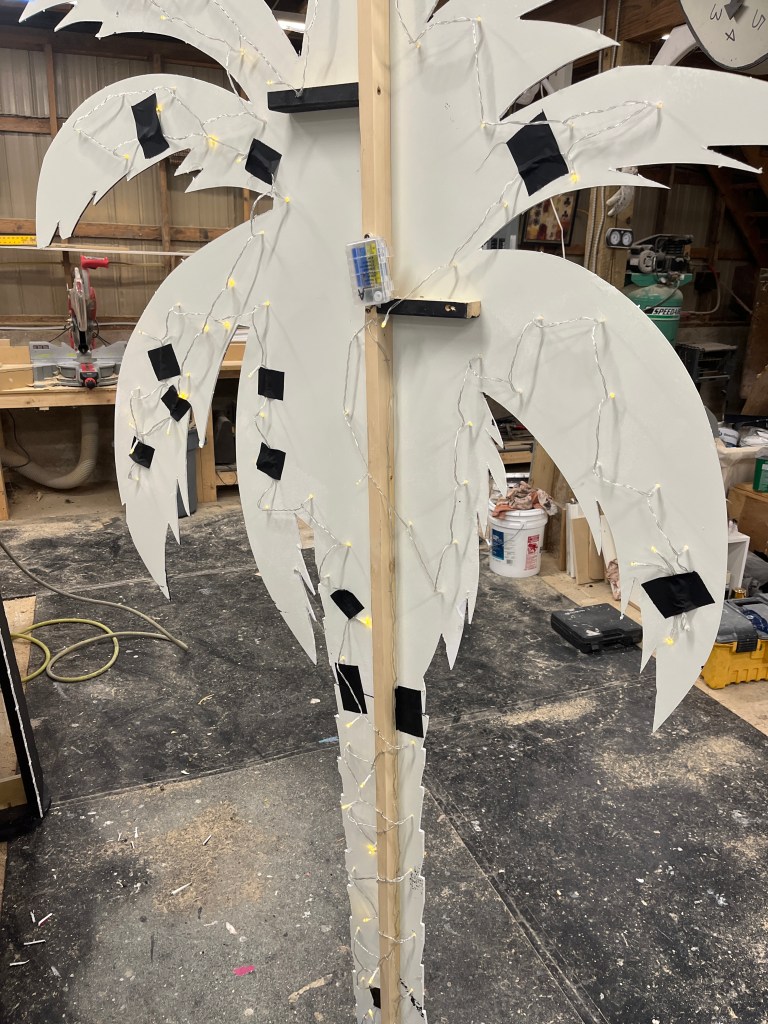

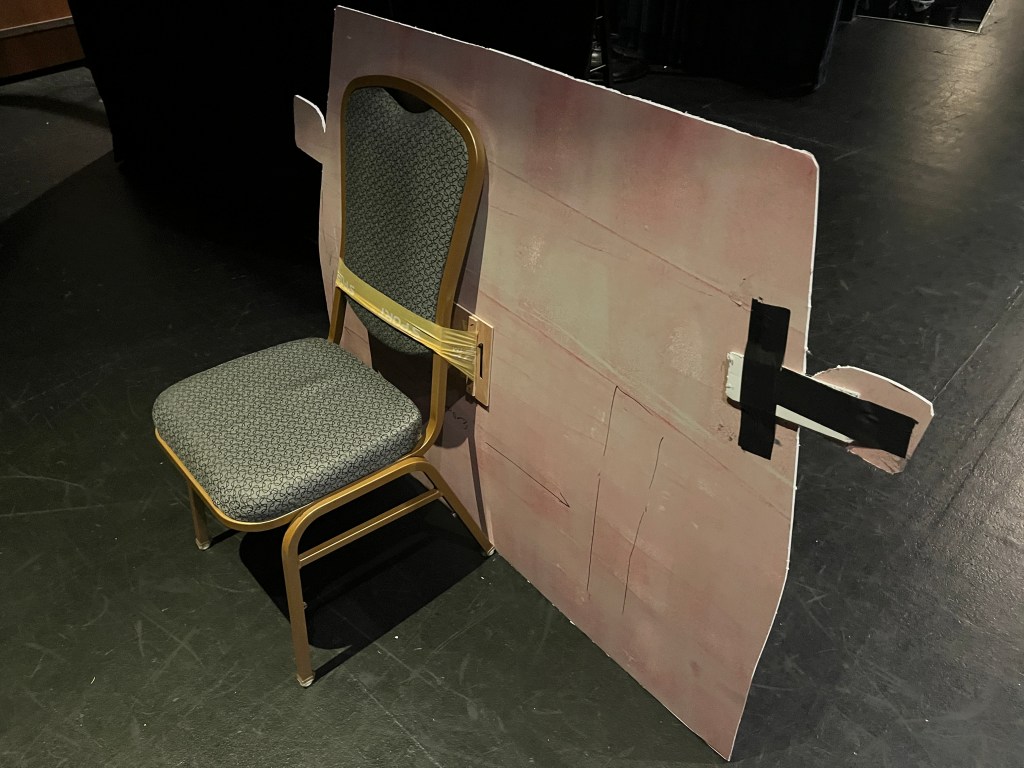

Here are some photos from the build.

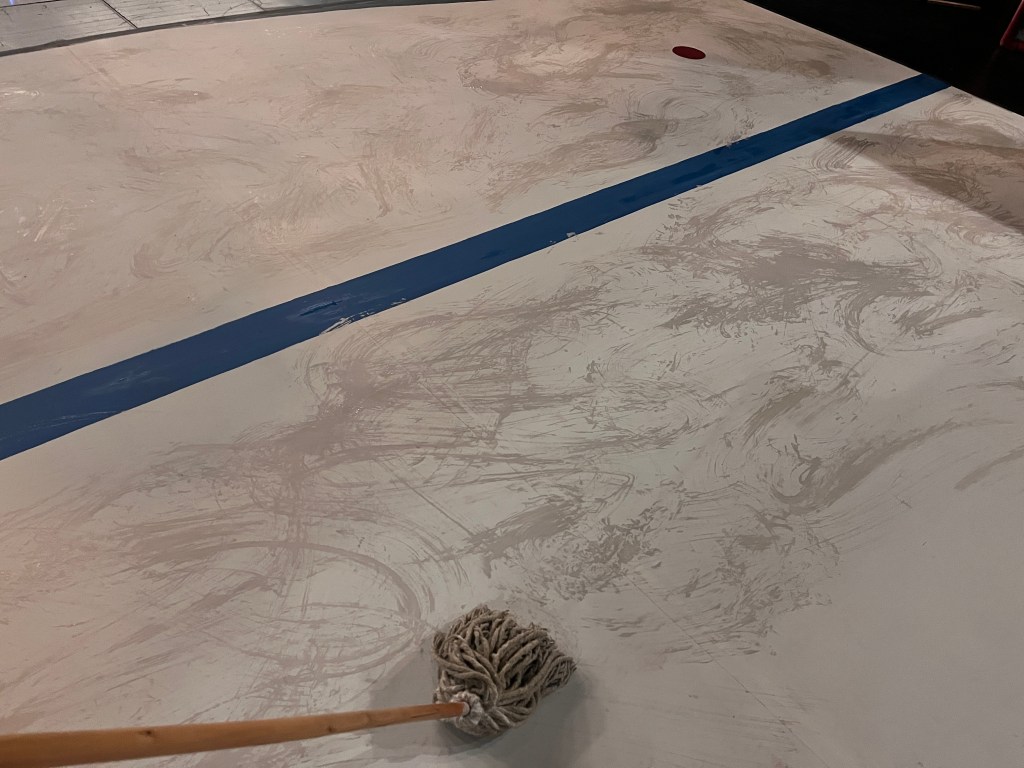

As you can see it is basically a hockey rink with some furniture. A few more photos once painting started:

And a few photos from tech week:

The “ice” turned out better than I expected. We used cheap sheet vinyl sourced from our local End of the Roll. I painted the bottom of it a light grey (it still looked bright white under lights). Then added some other colours to make it look dirtier, a couple coats of clear coat to protect it… it lasted the whole run but definitely got scuffed up by the hockey sticks and boots.

Official production photos to come….