Dorothy asked for a roof over their deck.

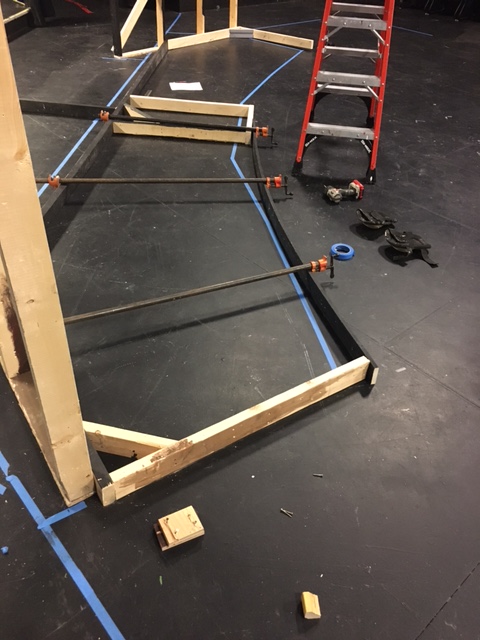

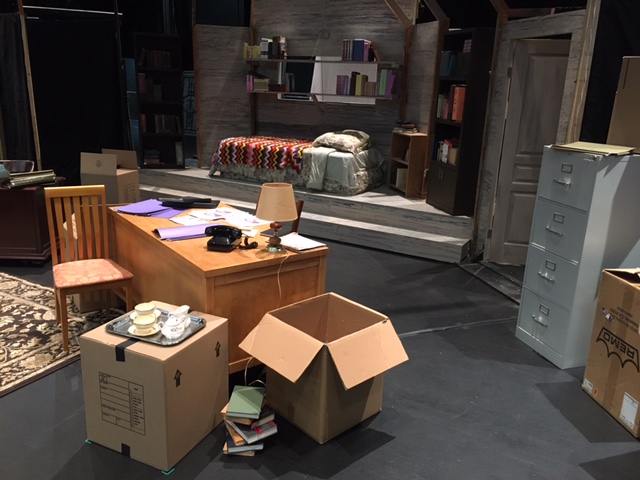

There was not a lot of room to get over the storm door and still have some slope without hitting your head on the other end. But I managed to get a 5% slope (would have liked to have more).

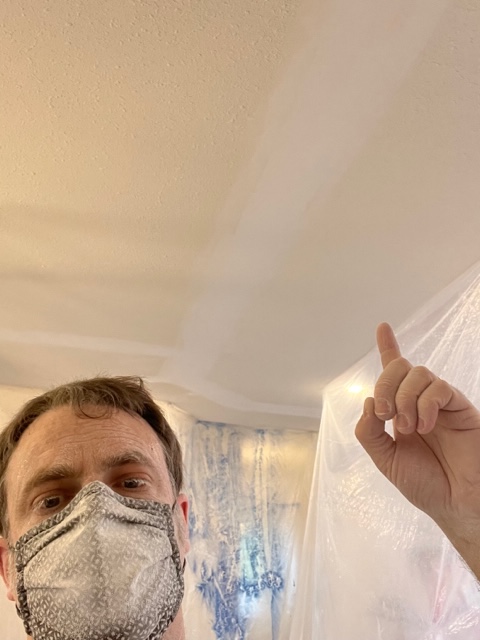

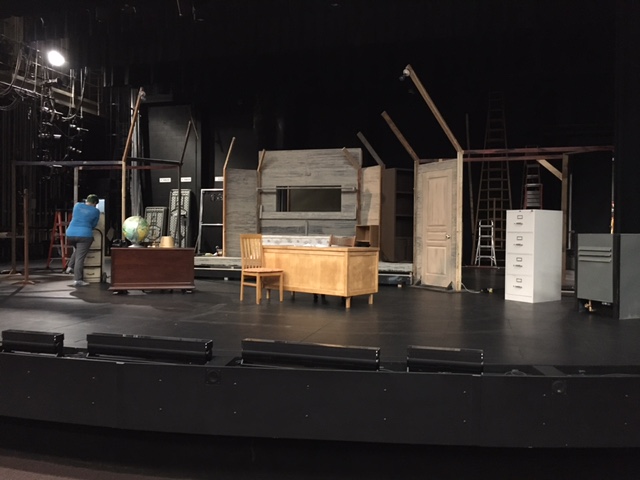

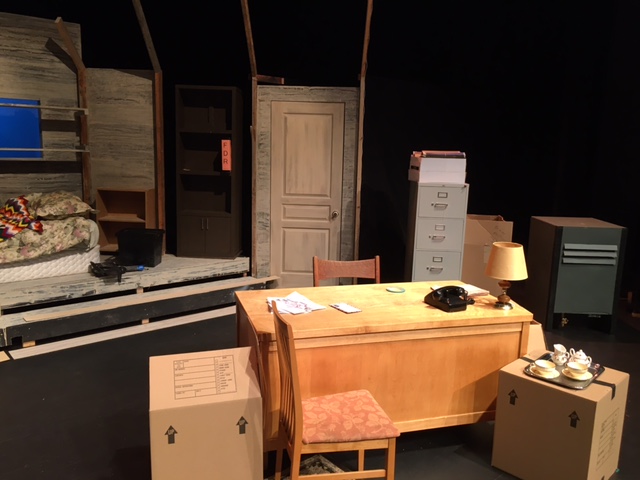

Before photos:

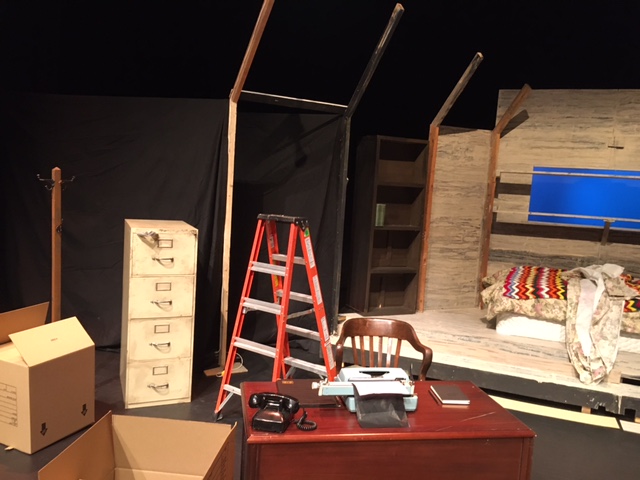

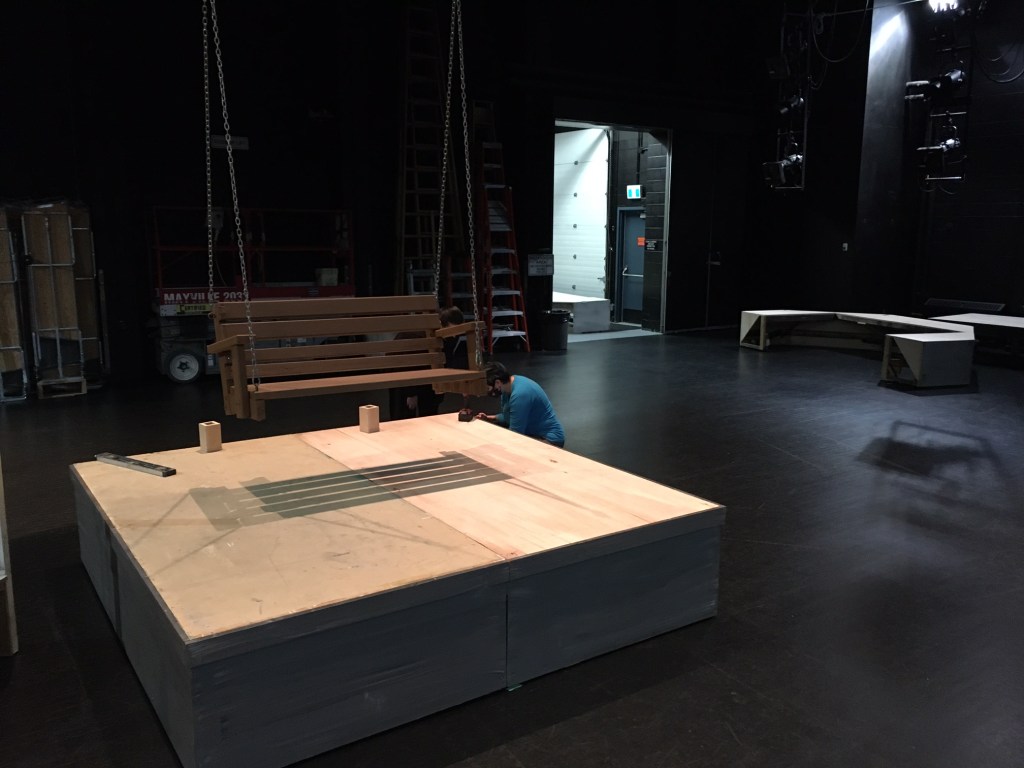

I used 2x4s to build the frame and attached it to the railings. There is not a lot of weight. Normally thicker posts and joists would be recommended.

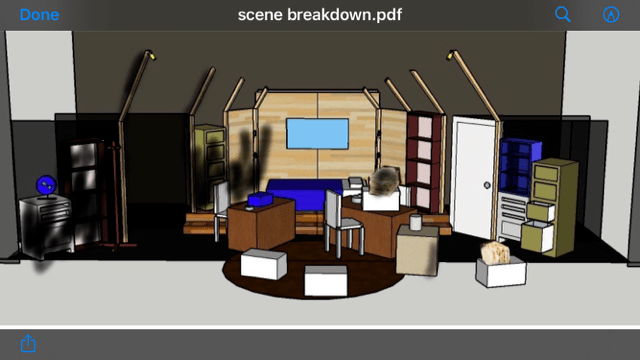

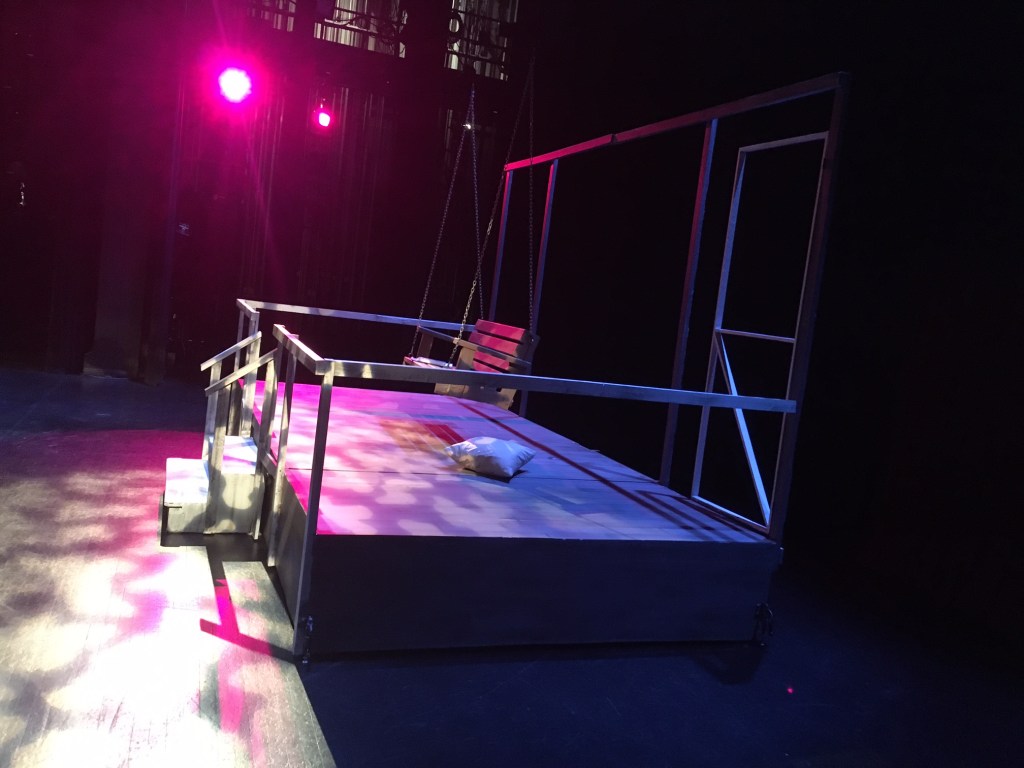

We chose clear PVC Palruf roofing as it was the most cost effective. It is installed using screws with rubber washers. Holes must be pre-drilled and larger than the screw to prevent cracking.

The deck will be more usable now that it is covered, as we get a lot of rain here. Will it need some maintenance? Probably. I have fixed another similar roof where the northeast wind blew some sheets loose. Will it hold snow? I think so! It will block UV rays, not heat; shades can be installed below the joists/blocking.